Latest News

My latest ramblings. Enjoy! I definitely got important things to say

My latest ramblings. Enjoy! I definitely got important things to say

For the sixth Terafood newsflash we want to show you the project video – watch it here: https://vimeo.com/387968788

Voor de zesde Terafood newsflash willen we jullie de projectvideo tonen – bekijk hem hier: https://vimeo.com/387968788

Pour le sixième Terafood newsflash nous souhaitons vous montrer la vidéo du projet – regardez-la ici: https://vimeo.com/387968788

What happens in the cleanroom… innoveert ons voedselverpakkingssysteem!

Onze supermarkten zijn dagelijks gevuld met lekkere en verse voedingsproducten dankzij continue innovaties in de agrovoedingsindustrie. Voor producten die snel bederven – denk aan zeevruchten, vis, vlees, verse groenten, enz. – worden echter de ‘ten minste houdbaar tot’ en de ‘te gebruiken tot’ datum zo kort mogelijk gehouden om publieke gezondheidsrisico te minimaliseren. Helaas leidt dit ertoe dat perfect eetbaar voedsel af en toe toch in de vuilbak belandt.

Het Terafood project wil dit probleem aanpakken door een ultragevoelige voedselverpakkingssensor te ontwikkelen die de versheid van een product in real time kan meten zonder de beschermende atmosfeer van de voedingsverpakking te verbreken. Om dit te doen hebben de Franse en Belgische Terafood partners een methode gecreëerd die berust op de interactie van de productomgeving met terahertz (THz) licht. Een voedingsproduct dat bederft zal karakteristieke aromatische componenten en gassen produceren, beter gekend als Volatiele Organische Componenten of VOC’s. Elk van die moleculen absorbeert THz licht op een specifieke manier, wat ons toelaat om een chemische vingerafdruk van de gassen in de verpakking te meten. Dit is een unieke eigenschap van THz licht: de mogelijkheid om doorheen verpakkingsmaterialen te kijken en tegelijkertijd zeer specifieke moleculaire absorptie te vertonen.

Een van de grote uitdagingen om deze methode te kunnen gebruiken in een verpakkingssensor bestaat erin om deze kleine interactie detecteerbaar te maken. Terahertz licht bevat relatief weinig energie, wat positief is omdat het voorkomt dat het licht het voedselmateriaal zou afbreken (zoals bij X-rays het geval is), maar wat negatief is omdat het niet krachtig genoeg is om gedetecteerd te worden door een optische sensor. Hiervoor is micro fabricering nodig.

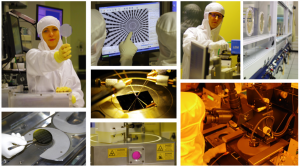

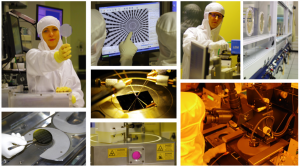

Een unieke kijk in de cleanroom en het microfabricatie centrum bij IEMN (gedeeld CNRS onderzoekslabo)

Na een jaar ontwikkelen is het consortium erin geslaagd een platform van verschillende structuren samen te brengen op een enkele silicone chip, kleiner dan een duizendste van een millimeter. Die structuren worden vervolgens zeer precies en efficiënt gelinkt, zodat al het licht dat van een THz lichtbron komt met beperkt verlies verzameld en geleid kan worden naar een analysezone, waar de interactie met de atmosfeer plaatsvindt en een groot deel van de optische kracht geconcentreerd wordt. Op die manier wordt deze minuscule chip een complete sensor die een gevoelige en correcte analyse van z’n omgeving toelaat. Een deel van deze microgefabriceerde sensor werkt als een kleine microfoon (slechts een honderdste van een vierkante millimeter!) die de vibraties versterkt van de gasmolecules die het THz licht geabsorbeerd hebben. Deze microfoon genereert dan een elektrisch signaal dat dient als een readout voor de sensor.

Dit alles is enkel mogelijk dankzij het gebruik van fotolithografische technieken en plasmagravuren, technieken uit de micro-elektronische industrie. Deze methodes zijn enkel realiseerbaar in een extreem nette omgeving, de cleanroom genoemd. De industriële partner van het project – Vmicro – gebruikt haar materiaal in de cleanroom van het Institute of Electronics, Microelectronics and Nanotechnology (IEMN), op de wetenschapscampus van de Université de Lille.

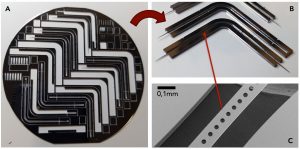

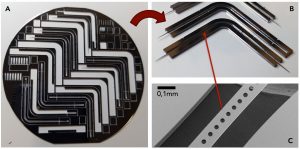

De partners hebben nu een modulair platform om sensors te maken en te optimaliseren volgens de specifieke noden van de voedingsverpakkingsindustrie. Dit platform heeft het mogelijk gemaakt om reeds twee generaties prototypes te maken. Dankzij deze prototypes konden de partners bewijzen dat THz licht weldegelijk gevangen kan worden in een klein volume (in de orde van 0,001 mm³) zonder iets van z’n kracht te verliezen. Deze kleine ‘vang’-gaatjes zijn zichtbaar in kader C van de foto’s hieronder. In een volgende stap zullen deze gaatjes bedekt worden met een erg dun microfoon membraan om de principes van de sensor te vervolledigen. Zo zijn de Terafood partners er nu dus erg dichtbij om “te luisteren naar de versheid van je eten”!

A: Silicium wafer bestaande uit verschillende prototypes. B: Sensoren losgemaakt uit het substraat en klaar voor gebruik.

C: Close-up van de resonatoren in de sensoren, de gaatjes hebben een diameter van 50 µm en zijn vervaardigd met een precisie in de orde van een micrometer (1 duizendste van een millimeter).

Bron en meer info:

Met de steun van het Europese Fonds voor Regionale Ontwikkeling en de provincie Oost-Vlaanderen.

Ce qu’il se passe dans la salle blanche… innove notre système emballage alimentaire

Chaque jour, les supermarchés sont pleins d’aliments délicieux et frais, grâce aux innovations continuelles dans l’industrie agro-alimentaire. Mais pour les denrées rapidement périssables comme les fruits de mer, le poisson, la viande, les légumes frais, etc. la ‘date de durabilité minimale’ et la ‘date limite de consommation’ sont réduites au minimum pour minimiser les risques de santé publique. Malheureusement, ceci provoque la gaspillage des nourritures parfaitement consommable.

Le projet Terafood a pour objectif la mise au point de capteurs ultra-sensibles permettant de mesurer en temps réel la fraîcheur des aliments à l’intérieur des paquets sans les ouvrir. Pour faire ça, les partenaires Terafood de la Belgique et la France ont créé une méthode qui est fondée sur l’interaction de l’environnement du produit avec lumière terahertz (THz). Un aliment qui est en train de se détériorer produira des components aromatiques et gazeuses caractéristiques, connus comme Composés Organiques Volatiles (COV). Chaque type de ces molécules absorbe lumière THz dans une manière spécifique, résultant dans une empreinte chimique du content gazeuse de l’emballage. C’est une propriété unique de lumière THz: être capable de regarder travers des matériaux emballage et en même temps exposer absorbation moléculaire très spécifique.

Afin de pouvoir utiliser cette méthode dans un capteur emballage, un des grands défis est de rendre cette petite interaction détectable. Lumière terahertz est relativement basse en énergie, ce qu’est positif parce qu’il évite la dégradation de la nourriture à cause de la lumière (par exemple avec rayons X), mais est négatif parce qu’il n’est pas assez fort pour être détecté par un capteur optique. C’est là qu’intervient la micro fabrication.

Regarde unique dans la salle blanche et centre micro-fabrication de IEMN (mutuel CNRS recherche labo)

Après un an de développement, les partenaires ont uni une plateforme des structures différentes sur un seul capteur silicone, plus petit qu’une millième d’un millimètre. Après, ces structures sont liées très précisément et efficacement, les permettant de collecter tous lumières provenant d’une source lumière THz et de guider cette lumière avec une perte minimale vers une zone d’analyse, où l’interaction avec l’atmosphère prends place et une grande partie de la force optique est concentrée. Comme ça, cette puce minuscule devient un capteur complet qui permet une analyse sensitive et correcte de son environnement. Une partie de ce capteur microfabriqué agit comme une petite microphone (jusqu’une centième d’un millimètre carré) qui amplifiera les vibrations des molécules gazeuses qui ont absorbé la lumière THz. Cette microphone génère un signal électrique qui sert comme une lecture pour le capteur.

Tout ça n’est que faisable grâce à l’usage des techniques photolithographie et gravure plasma, des techniques provenant de l’industrie micro-électronique. Ces méthodes sont uniquement réalisable dans un environnement extrêmement propre, la salle blanche. Le partenaire industriel du projet – Vmicro – opère son équipement dans la salle blanche de l’Institut de Electroniques, Microélectroniques et Nanotechnologie (IEMN), localisé au campus scientifique de l’Université de Lille.

Les partenaires ont maintenant une plateforme modulaire afin de créer et optimaliser les capteurs selon les besoins spécifiques de l’industrie emballage nourritures. La plateforme l’a déjà rend possible de réaliser deux générations de prototypes. Ces prototypes ont permis aux partenaires de prouver que lumière THz peut être capter dans une petite volume (de l’ordre de 0,001 mm³) sans perte de son pouvoir. Ces pièges à trous petites sont visible dans cadre C des images dessus. Dans l’étape suivante ces trous seront couvert avec des membranes microphone très fines pour compléter les principes du capteur. Ainsi, les partenaires Terafood sont près à « écouter à la fraîcheur de vos nourriture » !

A : Un wafer de silicium portant plusieurs prototypes. B Capteurs détachés du substrat et prêt à l’emploi.

C : Zoom sur le résonateur dans le capteurs, les trous ont un diamètres de 50µm et sont réalisé avec une précision de l’ordre du micromètre (1 millième de millimètre).

Source et plus d’info

Avec le soutien du Fonds Européen de Développement Régional et la province de Flandres Est.

What happens in the cleanroom… innovates our food packaging system!

Supermarkets are filled with delicious and fresh food products everyday thanks to continuous innovations in the agrifood industry. However, for products that spoil fast – think of seafood, fish, meat, fresh vegetables, etc. – ‘best before’ and ‘use-by’ dates are kept as short as possible to minimize the risk of public health issues. Unfortunately, this causes a lot of perfectly edible foods to be wasted.

The Terafood project aims to tackle this issue by developing an ultra-sensitive food packaging sensor that can measure the freshness of the product in real time without having to open the protective food packaging environment. To do so, the Terafood partners from France and Belgium created a method that relies on the interaction of the product’s environment with terahertz (THz) light. A foodstuff that is going bad will produce characteristic aromatic and gaseous compounds, so called Volatile Organic Compounds or VOCs. Each type of these molecules absorbs THz light in a specific way, allowing a chemical fingerprint of the gaseous content of the package. This is a unique property of THz light: being able to « see-through » package materials while at the same time exhibiting very specific molecular absorption.

To be able to use this method in a packaging sensor, one of the major challenges is to make this small interaction detectable. Terahertz light is relatively low in energy, which on the positive side avoids that the light degrades the food material (as for instance with X-rays), but on the downside is not powerful enough to be detected by an optical sensor. This is where micro fabrication comes in.

Unique peek in the cleanroom and micro-fabrication center of IEMN (joint CNRS research lab)

After one year of development, the consortium has now managed to bring together a platform of different structures on a single silicon chip, smaller than a thousandth of a millimeter. These structures are then linked very precisely and efficiently, allowing it to collect all light coming from a THz light source and to guide that light with minimal loss towards an area of analysis, where the interaction with the atmosphere takes place and a large part of the optic power is concentrated. In this way, this miniscule chip becomes a complete sensor that allows sensitive and correct analysis of its environment. Part of this microfabricated sensor acts as a tiny microphone (only one hundredth of a square millimeter!) that will amplify the vibrations of the gas molecules that have absorbed the THz light. This microphone generates an electrical signal that acts as a readout for the sensor.

All of this is only feasible thanks to the use of photolithography techniques and plasma engraving, techniques coming from the micro-electronics industry. These methods are only realizable in an extremely neat environment, called the cleanroom. The industrial partner of the project – Vmicro – operates its equipment in the cleanroom of the Institute of Electronics, Microelectronics and Nanotechnology (IEMN), located at the University of Lille’s Science campus.

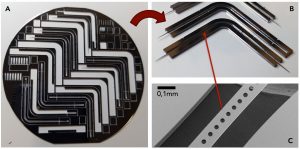

The partners now have a modular platform in order to create and optimize the sensors according to the specific needs of the food packaging industry. The platform has made it possible to already realize two generations of prototypes. These prototypes have allowed the partners to prove that that THz light can indeed be trapped in a tiny volume (of the order of 0,001 mm³ ) without losing any of its power. These tiny hole-‘traps’ are visible in frame C of the images below. In a next step these holes will be covered with very thin microphone membranes to complete the principles of the sensor. As such, the Terafood partners are very close to « listen to the freshness of your food »!

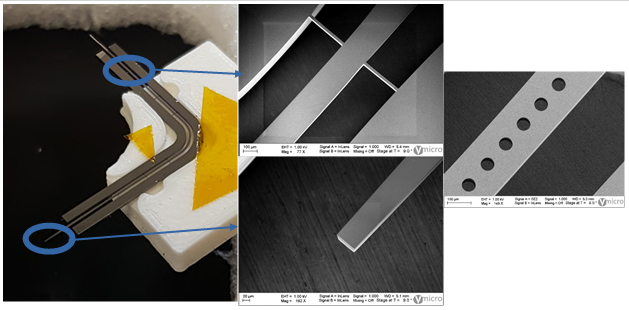

A: Wafer in silicon consisting of different prototypes. B: Sensors detached from the wafer and ready to use.

C: Close-up of the resonator structure in the sensor. The holes have a diameter of 50µm, with a precision in the order of 1 µm (1 thousandth of a millimeter).

Source and more information

With support of the European Regional Development Fund and the province of East-Flanders.

TERAFOOD Newsflash, February 2019

A teragood alternative for expiration dates?

The discussion on expiration dates (best before and use by) has been going on for many years now, mainly because of their impact on food waste. Expiration dates are hard to estimate, and moreover dependent on the circumstances in which the products are transported and preserved. Real time supervision of the quality of a food package’s content is still a somewhat far-fetched dream, but realizing this would allow a substantial reduction in food waste and therefore lead to not only an economical but also an important ecological breakthrough.

This dream is slowly starting to become real, with a new millimetric scale system that is developed within the TERAFOOD project (https://terafood.iemn.fr/). The system uses light at TeraHertz (THz) frequencies to monitor the chemical content of the headspace of a food package in real time. The advantageous properties of THz frequencies are that they can go through almost all types of packaging materials, but also strongly interact with most volatile organic compounds (VOCs) that form during food spoilage. This THz food sensor uses a so-called photoacoustic technique converting a THz signal into an easier detectable acoustical signal (sound)1.

What’s unique in this TERAFOOD project, is the scale in which the sensor can be produced. Using a Silicium-based chipscale technology not only allows for a compact technology but also for parallelized chipscale mass manufacturing which enables a reduction of costs. However, a disadvantage of this Silicium-based chip is that it can be defined as a glass particle, which is not allowed in food packaging. Although a promising technology, it will not be ready for implementation just yet.

How does the sensor work?

The TERAFOOD sensor is based on a triply resonant mechanism (patent pending) to achieve an enhancement of the measured signals. An important first step towards such an integrated sensor is the realization of a Si-waveguide to control the propagation of the light on the chip at frequencies that cover the absorption lines of typical spoilage gases (ammonia, hydrogen sulfide, ethanol).

The dimensions chosen for this waveguide confine and guide the light at frequencies between 500 GHz and 3 THz, a frequency range containing many spectral lines of these VOCs. In order to guide this light efficiently inside the silicon layer, a “suspended” beam of just a few hundredths of mm2 has been realized using advanced clean room techniques by engineers of Vmicro, a start-up company and partner in the TERAFOOD consortium.

The feat here has been to realize “floating” Si-beams of micron dimensions with a total length up to several centimeters. Moreover, Vmicro’s engineers optimized etching processes that made it possible to pattern circular holes with a diameter of a couple of hundredths of a mm inside these suspended beams (known as photonic crystals). In this way the gases that need to be detected can be efficiently captured and the guided THz light is allowed to interact strongly with the VOCs. These hole patterns have an additional role of acting as an artificial mirror trapping the light for a sufficiently long time in that part of the Si-waveguide where the gases are captured. The pictures below illustrate the scale, the dimensions and the technological processes of the fabricated test structures.

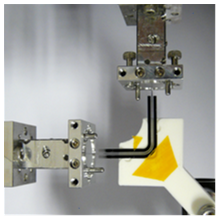

To validate that it is possible to control and guide the light inside this chip, we made a 90-degree bended channel as shown in Figure 2 below. A measured signal on the detector can only occur if the suspended Si-channel is truly guiding the THz light. However, the final sensor will obviously not include such a bend. Moreover, the THz light in the guiding structure will probably be coupled by other means than shown in Figure 1.

The experimental measurement setup shown here is primarily intended to provide a proof of principle demonstration that THz light can truly be confined and guided on a sub-mm integrated Si-chip. The techniques used for this demonstration are at the moment high tech lab instruments.

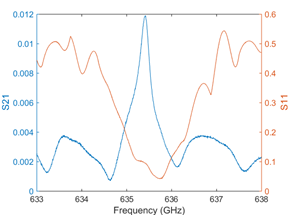

Figure 3 shows a typical measured output signal of the above experiment. As a function of frequency, the red and blue curves illustrate the light that is respectively reflected by and transmitted through the guide. It can be clearly seen that due to the specifically chosen dimensions of the patterned hole mirrors a THz signal close to the targeted frequency 635.5 GHz – corresponding to a strong absorption line of ethanol – is very selectively trapped and guided by the suspended Si-beam. This validates the confinement of the light at the resonance frequency corresponding to the targeted gas and the reflection of the other frequencies.

With this experiment, one essential building block of the TERAFOOD sensor has been validated. The next technological run will concentrate on combining such waveguides with gaseous environments containing small calibrated concentrations of the targeted gas. The strongly confined THz light is then expected to periodically heat this gas and actuate a membrane that covers one of the patterned holes. Measuring the movement of this membrane will then result in the detection of the trace gas.

With this experiment, one essential building block of the TERAFOOD sensor has been validated. The next technological run will concentrate on combining such waveguides with gaseous environments containing small calibrated concentrations of the targeted gas. The strongly confined THz light is then expected to periodically heat this gas and actuate a membrane that covers one of the patterned holes. Measuring the movement of this membrane will then result in the detection of the trace gas.

Source and more information

· If you want more information on the project, do not hesitate to contact the project coordinator Mathias Vanwolleghem – mathias.vanwolleghem@iemn.univ-lille1.fr

· If you are interested to become a member of the advisory board of this project, you can contact Isabelle Sioen – Isabelle.Sioen@UGent.be

With support of the European Regional Development Fund and the province of East-Flanders.

Submillimetre and THz spectroscopy: an effective tool for monitoring the freshness of foods of various kinds?

During the first period of the Terafood project (https://terafood.iemn.fr/) several relevant freshness indicator gasses have been identified via lab tests on Atlantic salmon (Salmo salar) (more info available in first Terafood newsflash [1]. Now the gasses indicating early spoilage are known a new approach is used to analyse surrounding gasses in order to determine the microbial activity (and linked to that the freshness) of a packaged target food product. For this purpose submillimeter and THz absorption spectroscopy is potentially a very attractive solution, as it allows to obtain extremely clear signatures (at least at low pressure) of the different gasses in complex mixtures.

In principle, the THz and submillimetre wavelength offers excellent selectivity in gas detection. To detect and identify the gasses tracers with a strong dipole moment to be suitable for trace detection are needed. To illustrate this, an existing spectrometer developed at the ‘Physico-Chimie Laboratory of the Atmosphere’ in Dunkerque has been adapted for the temporal monitoring of a target molecule within a gas mixture. The principle of the experiment is shown in Figure 1. A microwave source multiplied in frequency is used to cover the frequency range of 100 to 900 GHz (3 to 0.333 mm wavelength). An absorption cell ensures the interaction between the radiation and the gas under study. A Schottky diode at room temperature is used for signal detection. The sweeping frequency of the radiation source and the detection of the associated signal allow to reveal absorptions at characteristic frequencies of the target molecules present in the gas cell (see Figure 2).

Figure 1 : Experimental setup to measure molecular absorption in the submillimeter THz range

Provided that the spectroscopic parameters of the target molecule are known, it is then possible to deduce its concentration. In this example, formaldehyde was clearly identified and quantified at the ppm level. In order to improve the signal-to-noise ratio of this technology a frequency modulation technique with a second harmonic demodulation can be used. The next step in the project consists of carrying out a feasibility experiment on a sample of Atlantic salmon measuring the identified spoilage gas molecules in the head space of a packaged sample in order to improve the technology and to propose a first prototype of the system.

Figure 2: Absorption signal of formaldehyde in a complex mixture

With support of the European Regional Development Fund

Focus on spoilage – volatile organic compounds (VOCs) in food quality monitoring

Spoilage of highly perishable food products such as fresh fish is typically due to microbial activity that leads to the generation of volatile organic compounds (VOCs). These compounds could be used as spoilage indicators and thus for quality monitoring of the packaged food product. The TERAFOOD project is investigating innovative analytical techniques for the identification and quantification of potential food spoilage indicators.

Food spoilage is a major economic and ecological concern in the modern society. In industrialized countries, more than 40 % of all yearly food losses has been estimated to take place at the retail or consumer level (FAO, 2011). A great part of food waste originates from refrigerated products that have a very short shelf life, such as fresh seafood. In this case, spoilage is usually due to microbial activity and the consequent generation of volatile organic compounds (VOCs) in the package headspace. Even though spoiled food does not necessarily pose an infection risk, offensive off-odors and other unpleasant changes in the sensory quality render the product unfit for consumption. Development of innovative quality monitoring systems thus calls for the identification of VOCs that indicate food spoilage.

The TERAFOOD project, coordinated by the CNRS (Institute of Electronics, Microelectronics and Nanotechnology, Lille) and involving several academic and industrial partners, aims at the development of a compact and low-cost commercial terahertz-sensor that can be used for monitoring the quality of packaged food products by VOC detection (Flanders’ FOOD, 2017; UGent, 2017). Introducing the sensor in food packages allows real-time quality monitoring at any time during storage without opening the package and has thus the potential to greatly reduce food waste. However, every food product has its characteristic spoilage processes that depend on several intrinsic and extrinsic factors. To allow efficient quality monitoring, information is thus needed about VOCs and their concentration levels in different food products as well as under different packaging and storage conditions. Identification and quantification of VOCs that indicate food spoilage is carried out at the Department of Food Safety and Food Quality at Ghent University.

During the first semester of the project, spoilage of Atlantic salmon (Salmo salar) packaged under different gaseous atmospheres was examined (Fig. 1).

Fig. 1. The experimental setup of Atlantic salmon.

Microbiological, chemical and sensory changes were analyzed on a regular basis throughout storage time. VOCs produced in the package headspace were monitored with selected-ion flow-tube mass spectrometry (SIFT-MS) that allowed fast and sensitive quantification of VOCs directly from the actual food packages. The obtained results show that the evolution of the VOC profile and the emerging off-odors depend on the applied storage conditions and that several VOCs can be considered as potential spoilage indicators of Atlantic salmon. For the sensor development, the results provide with essential information about spoilage-related VOCs and highlight the sensitivity levels needed for their detection. During the next semester of the project, advanced multivariate statistical analyses will be carried out to further enhance the characterization of most potential spoilage indicators. Furthermore, the developed experimental setup and methods will be extended to new food products.

More information:

Lotta Kuuliala – Lotta.Kuuliala@UGent.be

If you are interested to become a member of the advisory board of this project, you can contact Isabelle Sioen – Isabelle.Sioen@UGent.be

Compact and low-cost Terahertz sensor for monitoring of food quality

The aim of the project is to develop a commercial food sensor .This sensor makes it possible to check the quality of packaged food within a package . Because such a sensor will be able to check the quality of individual packages at any time we think application of such a sensor will help to reduce food waste in the food industry drastically in the future. By pushing back the problem of food waste and food spoilage in the food industry, which creates a lot of prosperity in the border region, we assume that the project will have a lot of influence on the regional economy .

The consortium consists out of both industrial and academic partners with the necessary expertise to produce the sensor. Moreover, the consortium has partners (Food2Know, Flanders’ FOOD, …) that are specialized in bridging the space between the academic world and the industry. These partners will be responsible for valorization and the dissemination of the sensor technology. Furthermore, they will generally disseminate the terahertz technology through their respective networks and look for new applications in cooperation with experts from the industry and the academic world.

Université de Lille – coordination institute

Université de Lille – coordination institute

Mathias Vanwolleghem (mathias.vanwolleghem@univ-lille1.fr)

Université du Littoral Côte d’Opale

Gael Mouret (gael.mouret@univ-littoral.fr)

![]() VMicro

VMicro

Benjamin Walter (benjamin.walter@vmicro.fr)

Universiteit Gent – Department of Information Technology

Bart Kuyken (bart.kuyken@ugent.be)

Mattias Verstuyft (matthias.verstuyft@ugent.be)

Universiteit Gent – Lab of Food microbiology and food preservation

Universiteit Gent – Lab of Food microbiology and food preservation

Frank Devlieghere (frank.devlieghere@ugent.be)

Lotta Kuuliala (lotta.kuuliala@ugent.be)

Universiteit Gent – Food2Know

Isabelle Sioen (isabelle.sioen@ugent.be)

F

landers’ Food

landers’ Food

Gus Verhaeghe (gus.verhaeghe@flandersfood.com)

Veerle De Graef (veerle.degraef@flandersfood.com)